Frequently Asked Questions

General FAQs

Answers to commonly asked questions about Ocado Intelligent Automation (OIA), the Ocado Storage & Retrieval System (OSRS), and Chuck AMR products.

Yes, and we provide three approaches to this:

Chuck Picking Alongside OSRS: Deployed permanently for awkward inventory that fits best on (or is optimally picked from) traditional racking; for C-mover items; or temporarily, to cover bursts of activity during demand peaks.

Chuck Before OSRS: Launch Chuck in a matter of weeks, while building OSRS alongside/nearby

Chuck Movements Supporting OSRS: For E-Commerce, Chuck can carry materials, such as picked orders or erected boxes, to pack stations.

OIA serves diverse industries beyond grocery, including (but not limited to) Healthcare & Pharma, Fashion & Apparel, 3PL, Industrial, and OEM parts, as well as consumer packaged goods (CPG). We continually explore new industries to enhance efficiencies. Our systems are highly customizable and will enhance operational efficiency in a wide range of potential scenarios - please contact us if you would like to learn more about which system could be the right fit for you.

OSRS and Chuck AMR boost productivity, enhance picker experience, improve accuracy, and minimize risk.

OSRS provides seamless scalability, high storage density, ambient and cold storage, and high availability.

Chuck AMR quickly integrates into existing warehouses, surpassing manual SLA and accuracy goals, expediting tasks and training, reducing picker fatigue, and delivering real-time data insights.

Both offerings enable high throughput while significantly reducing fixed asset, conveyor, and labor costs.

We use computer simulation models to ascertain and verify the optimal configuration for your application.

Chuck AMR can be deployed within hours.

OSRS installations vary widely in size, component count, and building requirements. Each instance of OSRS is uniquely tailored to meet the specific needs of our customers' current and future operations. Typically, we complete a standard project from contract to handover in 9-18 months. For urgent automation needs, Chuck AMR can be deployed as a stop-gap if required.

OSRS and Chuck are sold directly to customers and then installed and managed by dedicated Ocado Technology teams. We plan to work with integrators starting in 2025 and welcome inquiries from interested parties.

Chuck AMR can be rented and many of our customers have multi-year rental agreements. Existing customers can rent additional Chucks during peak periods or use our Flex-Chuck program for a portion of your fleet, enabling you to pay for extra capacity only when needed.

OSRS is currently a managed system—our engineering teams remain on site whenever it is operational.

Chuck AMR is designed to work alongside your workforce—associates can be trained on Chuck in a matter of minutes. Performance is monitored remotely and does not require OIA engineers to be present. Maintenance is performed and units replaced whenever required.

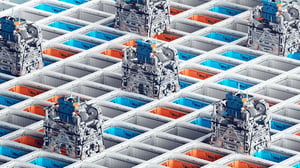

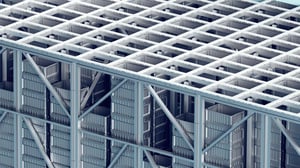

The Ocado Storage and Retrieval System (OSRS) offers extensive scalability in capacity and throughput, meeting evolving business needs. Its modular design enables robots and workstations to be added with zero downtime and grids to be expanded as your business grows.

Chuck AMR can similarly be scaled, simply by adding or removing robots. This enables you to efficiently meet changing throughput requirements and seasonal peaks.

When combined, the two solutions provide highly scalable warehouse automation.

If your question isn't listed, please use the "Talk With an Expert" form at the bottom of the page and we'll happily answer it for you.

@4x.png?width=642&height=166&name=OIA_Logomark_color_(R)@4x.png)