Industrial & OEM Parts

Intelligent Automation for Mission-Critical Supply Chains.

From automotive and aerospace to manufacturing, heavy machinery and utilities, the industrial and OEM sector now heavily depends on streamlined automation across its supply chains.

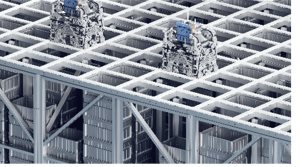

Managing intricate industrial supply chains involving numerous suppliers, parts, and components demands precise inventory control and efficient logistics. The Ocado Storage and Retrieval System (OSRS) streamlines industrial and OEM parts logistics by maintaining precision and reliability in handling critical components.

By optimizing inventories, OSRS ensures accurate stock balancing to aid industries such as automotive, aerospace, and heavy machinery in meeting production schedules, ensuring quality, and enhancing operational efficiency.

Industrial warehouse operations must also comply with industry-specific regulations, safety standards, and international trade laws—adding complexity to logistics and warehousing operations. Ensuring adherence while managing operations efficiently is a continuous challenge—one that OSRS enables through comprehensive traceability and innovations such as metal storage bins, which offer unparalleled fire resistance.

Industrial and OEM companies can quickly ramp up automation within their existing facilities with Chuck automated mobile robot (AMR). Chuck is a grid-free robot that's easy to deploy and scale, working alongside your human associates to constantly improve performance and lower variable cost per task.

OSRS: Key Benefits

Key benefits of the Ocado Storage and Retrieval System (OSRS) to the industrial and OEM sectors.

Store industrial components and chemicals securely within the grid, contained within metal bins to significantly reduce the risk of stock becoming damaged

Utilize smart stock ordering within the grid, as slower-moving SKUs move naturally towards the bottom of the grid while fast-moving SKUs rise to the top

Automate picking of a wide range of SKUs with on-grid robotic pick, with temporary order buffering to support customer order modifications throughout their ordering window

Accommodate both individual item and full case picking with our flexible OSRS pick workstations, designed to support a wide range of peripherals and handle multi-channel order profiles

Carry a far greater range of stock within the same occupied footprint. Compared to conventional pallet storage systems, OSRS' cubic storage grid requires significantly less aisle space

Unlock additional efficiencies in outbound sortation and dispatch processes by nesting delivery bins inside grid bins, with temporary order buffering to support customer order modifications

OMRS: Key Benefits

Key benefits of the Ocado Mobile Robot System (OMRS) to the industrial & OEM industry.

Simplify the handling of diverse parts and components with precise, automated workflows that optimize logistics for the industrial and OEM sectors.

Ensure rapid and accurate retrieval of critical components with OMRS’s advanced robotics, helping meet demanding production schedules in industries like automotive and aerospace.

Maintain efficiency while adhering to industry regulations, safety requirements, and trade laws with reliable, system-directed workflows and traceable operations.

Adjust seamlessly to fluctuating order volumes and peak periods with configurable solutions tailored for the complexities of OEM and industrial operations. Choose from diverse picking methods like discrete, batch, and zone picking.

Easily deploy and scale Chuck AMR to constantly improve performance, maximize floor space, reduce reliance on manual labor, lower variable cost per task and the total cost of fulfillment.

UDrive consistent performance across slotting, picking, replenishment, and packout, ensuring maximum throughput and operational efficiency throughout your distribution operations.

@4x.png?width=642&height=166&name=OIA_Logomark_color_(R)@4x.png)