Fashion & Apparel

Trend-Setting Automation for Fashion Retail.

Agility is the fashion and apparel retail industry’s most competitive advantage, followed by the ability to stock a diverse range of seasons, sizes and styles. OSRS offers retailers both, and more, for direct to consumer e-commerce and omnichannel applications.

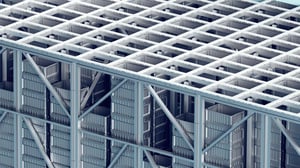

The Ocado Storage and Retrieval System (OSRS) enables rapid picking of diverse SKUs while automatically optimizing your inventory and ensuring careful and efficient handling of fashion and apparel items.

By streamlining logistics, OSRS assists in meeting fluctuating consumer demand, preserving the quality of delicate apparel and supporting the industry's need for rapid, seasonal inventory turnover and robust returns processes, all while maximizing storage density and protecting margins.

OSRS also meets seasonal peak challenges head-on, at times when operational efficiency and customer satisfaction traditionally become a real challenge.

For fashion and apparel retailers looking to prioritize speed of deployment over maximizing efficiencies in their existing infrastructure, our Chuck AMR (autonomous mobile robot) offers a lower-cost solution to increase productivity. Chuck is a grid-free robot that's easy to deploy and scale, working alongside your human associates to constantly improve performance and lower variable cost per task.

OSRS: Key Benefits

Key benefits of the Ocado Storage and Retrieval System (OSRS) to the fashion & apparel industries.

Deliver ever-shorter cycle times and reduced order cut-off periods with OSRS’ predictable, continuous throughput

Utilize smart stock ordering within the grid, as slower-moving SKUs move naturally towards the bottom of the grid while fast-moving SKUs rise to the top

Carry a far greater range of stock within the same occupied footprint. Compared to conventional pallet storage systems, OSRS' cubic storage grid requires significantly less aisle space

Accommodate both individual item and full case picking with our flexible OSRS pick workstations, designed to support a wide range of SKUs and handle multi-channel order profiles

Unlock additional efficiencies in outbound sortation and dispatch processes by nesting delivery bins inside grid bins, with temporary order buffering to support customer order modifications

Keep valuable inventory secured in the grid from start to end with full traceability and minimal human interaction

OMRS: Key Benefits

Key benefits of the Ocado Mobile Robot System (OMRS) to the fashion & Apparel industry.

Reduce onboarding time to minutes and enhance associate happiness and productivity with efficient system-directed workflows, supporting retention in competitive markets.

Adjust seamlessly to fluctuating order volumes and peak periods with configurable solutions tailored for the complexities of B2B distribution. Choose from diverse picking methods like discrete, batch, and zone picking.

Enhance throughput and meet tightened SLAs with advanced workflows and precise robotic operations that deliver accurate, fast order fulfillment.

Easily deploy and scale Chuck AMR to constantly improve performance, maximize floor space, reduce reliance on manual labor, lower variable cost per task and the total cost of fulfillment.

Effortlessly upgrade your distribution operation to OMRS with minimal downtime and integration ease.

Drive consistent performance across slotting, picking, replenishment, and packout, ensuring maximum throughput and operational efficiency throughout your distribution operations.

@4x.png?width=642&height=166&name=OIA_Logomark_color_(R)@4x.png)