Solutions

Dispatch Buffering and Sequencing

In high-throughput fulfillment environments, bottlenecks in dispatch processing can undermine even the most advanced automated operations. Most rely on onerous manual processes, or costly and complex secondary automation systems to deal with post-pick handling, storage and outbound sequencing.

Ocado Intelligent Automation (OIA) offers a more flexible, space-efficient approach to dispatch buffering and sequencing that radically streamlines the efficiency of your post-pick handling process by keeping picked orders within the Ocado Storage and Retrieval System (OSRS) grid until they are ready for dispatch.

By leveraging intelligent software-driven workflows, this method eliminates the need for additional buffering systems such as miniloads, shuttles or extensive conveyors. The result is a resilient, high-performance fulfillment process that mitigates risk and adapts to fluctuating demand without excess infrastructure or manual labor costs.

With deep expertise in high-velocity fulfillment operations, OIA has redefined the way warehouses manage outbound orders. Our innovative approach to dispatch buffering and sequencing enables warehouses to maintain high throughput while ensuring precise order availability at the right time.

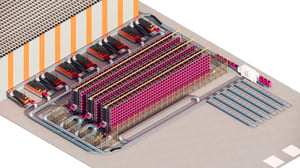

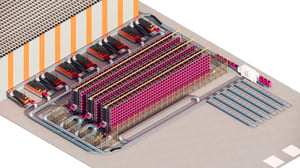

In-Grid vs. External Buffering Systems

By storing picked orders directly within the OSRS cubic grid, fulfillment operations reduce or completely remove reliance on secondary storage outside of the grid. Use the slider to compare how footprint and automation complexity are streamlined.

In-Grid vs. External Buffering Systems

By storing picked orders directly within the OSRS cubic grid, fulfillment operations reduce or altogether remove reliance on secondary storage outside of the grid - compare the impact on footprint and automation complexity below.

Key Benefits

Automating the return of picked orders back to the ASRS grid offers numerous unique advantages, from more precise and consistent throughput to greater resiliency due to minimized points of failure. It’s especially suited to operations shipping orders with larger average order sizes such as store or facility replenishment or mixed returns sortation.Unlike traditional systems that require picking in the exact dispatch order—leading to inefficiencies—our approach separates picking from outload sequencing. Software orchestrates the buffering of orders in an optimized sequence, allowing for flexible, just-in-time retrieval.

Storing picked orders within the grid eliminates the need for external buffer zones, freeing up valuable storage and operational areas. Our solutions make the most of your available storage volume, reducing build costs.

Our Pick+Store approach reduces integration complexity and costs. The grid can be optimized for better robot utilization, higher throughput, and smaller fleet sizes per pick. Minimizing single points of failure (SPOF) in outbound fulfillment cuts critical failure risk and maintenance load.

With the ASRS handling tasks dynamically, fewer manual interventions are needed, leveling out labor spikes and reducing over-provision of labor during peak hours. Additionally, a reduced number of workstations translates to lower staffing requirements, cutting operational costs while maintaining high throughput.

Software-driven design makes future upgrades a breeze, without requiring the sort of major physical reconfigurations needed in shuttle or conveyor systems. And a uniform, modular grid can be scaled up as needed by adding more grid and more robots.

Our Pick+Store approach restricts unauthorized or erroneous access, reducing risks of theft, misplacement, or damage. By keeping picked orders within the grid until dispatch, warehouses further minimize shrinkage, improve traceability, and ensure stock remains secure within a tightly managed fulfillment process.

Related Technologies

Unique to OSRS, Pick+Store returns packed orders to the same cubic ASRS grid that they were picked from.

Learn More >

Use your grid to securely store outbound orders prior to dispatch. The Combine+Separate Machine replaces complex, costly and risky integration of extra equipment & processes, simplifying your supply chain.

Learn More >

An on-grid robotic picking solution for the Ocado storage and retrieval system (OSRS), combining dexterous robotic arm hardware with proprietary artificial intelligence (AI).

Read More@4x.png?width=642&height=166&name=OIA_Logomark_color_(R)@4x.png)