Third-Party Logistics (3PL)

Scalable Automation That Meets Every Client’s Needs.

The 3PL sector is witnessing a surge in competition. Labor prices and shortages continue to rise along with increasing real estate and operational costs, all putting pressure on margins. Leading organizations are turning to automation to improve operational efficiency, take better advantage of high-value real estate and differentiate themselves in the marketplace.

Historically third-party logistics (3PL) companies have been able to rely on flexing labor across facilities to support natural or unplanned changes in operational demand. The increase in competition for labor is putting significant pressure on operating margins, especially for long-term client contracts and during peaks.

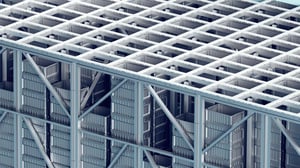

Operating in a diverse landscape catering to multiple clients demands adaptability and scalability. Winning logistics organizations are implementing automation to stabilize their labor challenges and outshine competitors. Ocado is uniquely positioned to help in that journey with flexible automation options—from our capital-and-infrastructure-light Chuck AMR solution to our flagship OSRS cubic storage solution, suited for applications demanding the highest throughput and storage density available.

OSRS’ minimal yet highly scalable footprint allows for efficient handling of diverse inventory types, supporting 3PLs in optimizing operations, meeting client demands, and ensuring precision in their supply chain. This scalability also enables OSRS to adapt to both natural and unplanned changes in operational demand, and to grow as client demands change.

OSRS: Key Benefits

Key benefits of the Ocado Storage and Retrieval System (OSRS) to the third-party logistics industry.

Deliver ever-shorter cycle times and reduced order cut-off periods with OSRS’ predictable, continuous throughput

Utilize smart stock ordering within the grid, as slower-moving SKUs move naturally towards the bottom of the grid while fast-moving SKUs rise to the top

Store stock safely and securely in-grid, then buffer and sequence for automatic load balancing to external pack or value added services (VAS) stations as needed

Accommodate both individual item and full case picking with our flexible OSRS pick workstations, designed to support a wide range of SKUs and handle multi-channel order profiles

Carry a far greater range of stock within the same occupied footprint. Compared to conventional pallet storage systems, OSRS requires significantly less aisle space

Unlock additional efficiencies in outbound sortation and dispatch processes by nesting delivery bins inside grid bins, with temporary order buffering to support customer order modifications

OMRS: Key Benefits

Key benefits of the Ocado Mobile Robot System (OMRS) to the third-party logistics industry.

Reduce onboarding time to minutes and enhance associate happiness and productivity with efficient system-directed workflows and robots - eliminating the need for arduous isle walks and manual cart pulls and supporting retention in competitive markets.

Adjust seamlessly to fluctuating order volumes and peak periods with configurable solutions tailored for the complexities of B2B distribution. Choose from diverse picking methods like discrete, batch, and zone picking.

Enhance throughput and meet tightened SLAs with advanced workflows and precise robotic operations that deliver accurate, fast order fulfillment.

Easily deploy and scale AMRs to constantly improve performance, maximize floor space, reduce reliance on manual labor and lower the total cost of fulfillment. Drive consistent performance across slotting, picking, replenishment, and packout.

Effortlessly upgrade your 3PL operation to OMRS with minimal downtime and integration ease. Our software integrates with your existing infrastructure, including any WMS.

Drive consistent performance across slotting, picking, replenishment, and packout, ensuring maximum throughput and operational efficiency throughout your distribution operations.

Online sales are increasing, which means returns are increasing as well. With our returns putaway capability, it's easier to get returns back on the shelves to maximize warehouse space and profitability.

@4x.png?width=642&height=166&name=OIA_Logomark_color_(R)@4x.png)