What is OSRS?

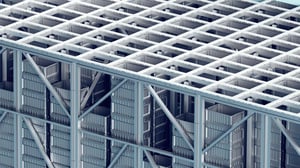

The Ocado Storage and Retrieval System (OSRS) is an ultra-high-density cubic automated storage and retrieval system (ASRS) combining world-proven automation with business intelligence.

How does the system and its components work together?

The Ocado Storage and Retrieval System (OSRS) addresses many complex supply chain challenges, drawing upon over 20 years of R&D experience in maximizing throughput and minimizing costs in our own warehouses. Workstations facilitate both the smooth induction of inventory into the cubic storage grid, and fulfillment of picking orders out of it. Our robots efficiently handle stock movement, with battery swap ensuring their uninterrupted operation. Robotic picking utilizes advanced technology for efficiency. WES software orchestrates system operations, ensuring fast fulfillment and high uptime, directing orders for dispatch or storage as needed.

How is OSRS different from other comparable solutions?

OSRS is the only single-cell robot-based cubic ASRS on the market. Robots take up a single square on the grid, reducing traffic congestion while maximizing stock access and robot availability. The grid's unique double-track layout enables bots to occupy adjacent spaces only millimeters apart. This patented design results in greater throughput than alternatives.

What happens if there's a technical issue with a robot on the grid?

The OSRS robot is highly reliable, with typically one failure per 1,000 hours of operation. In 95% of cases, the robot self-recovers without human intervention and without disrupting the grid. Robots also feature a 'limp mode' for automated self-recovery to a maintenance area. If physical human intervention is needed, the robot can be isolated in a 3x3 cell area of the grid until operations can be safely paused. Human access to the grid is only permitted once the Grid Access Safety System is engaged.

How long are preventative maintenance intervals?

OSRS Robots undergo fixed servicing every 3 months. We monitor for anomalies or performance degradation, enabling predictive maintenance or part replacement before failure, minimizing downtime.

How does OSRS talk/integrate with existing systems (other MHE)?

OSRS requires integration with the customer's business systems via APIs to facilitate seamless data exchange and synchronization. This ensures that OSRS can efficiently interact with existing warehouse management systems, order processing software, and other business applications, enabling streamlined operations and accurate information flow throughout the supply chain.

Does OSRS integrate with customers' existing WMS?

OSRS offers a standardized interface for easy integration with existing warehouse execution (WES) or management systems (WMS). Ocado has extensive experience providing comprehensive warehouse and supply chain management systems with enterprise integrations for many large retail customers worldwide.

Can OSRS operate in temperature-controlled (cold chain) environments?

OSRS is highly suited to refrigerated environments as low as 2℃, and is deployed globally in our own grocery customer fulfillment centres (CFCs). Our ability to consistently chill large areas of a warehouse means the grid provides ideal conditions for storing perishable items such as pharmaceuticals, biotechnology, cosmetics, horticulture, food, and more.

Why are projects that require ultra high throughputs suitable for OSRS?

The Ocado Storage and Retrieval System (OSRS) is particularly suited to high-throughput use cases due to its cubic design and operational capabilities that prioritize vertical density. Flexible bin storage and efficient picking routes reduce order fulfillment time, while continuous operation ensures high productivity. The modular grid allows scalable storage and throughput as customers' needs grow, while real-time data from the Warehouse Execution System (WES) software improves inventory accuracy and sequences SKUs dynamically over time, reducing order times.

Under which project situations and for what business needs is OSRS particularly advantageous?

The Ocado Storage and Retrieval System (OSRS) maximizes operational productivity and reliability within a given space, offering unmatched ROI. Our highly automated warehouse management focuses on efficiency, scalability, and safety, evolving with our customers' needs. See above for specific advantages that address business needs.

How does the solution manage short lead time orders?

For orders with short lead times, our robots can work outside regular hours to sequence stock for picking. Our WES software employs advanced algorithms and real-time data to optimize bin retrieval, coordinating robots and pick stations for efficient order picking. Completed orders can be sent directly from pick stations to dispatch without buffering, streamlining the process.

Can OSRS be optimized for both small and large order sizes?

Yes, we can optimize our solution types/designs for order size. For E-commerce (B2C), our designs prioritize low order sizes, while for replenishment B2B, they aim to maximize multiple delivery assets/cartons per order.

Do you support different layout configurations of picking in the solution?

Yes, the solution can be optimized for picking of orders into delivery assets for immediate onward processing, or for deferred action by temporarily storing them back into the grid. Layouts with or without a pick tunnel can cater to different throughput requirements and will be discussed as we explore your requirements.

How do you maintain accuracy in your solution?

The Ocado Storage and Retrieval System (OSRS) ensures end-to-end quality checks for order timeliness, accuracy, and process visibility. At our Induct Stations, operators are guided through stock induction with clear instructions and imagery, including inputting product shelf lives, aided by hand scanners. Each bin is individually traceable with unique identifiers throughout the process, preventing unauthorized inventory changes due to bin containment. High-speed cameras and UIs facilitate accurate order completion and stock replenishment at the next access point for picking.

How do we make sure we get the right dated products out of the grid? How do you manage product shelf lives in the solution?

The Ocado Storage and Retrieval System (OSRS) can operate based on either first in first out (FIFO), or last in first out (LIFO) valuation, depending on the customer's needs and the type of stock. Every item entering the grid is dated during induction, allowing us to track sell-by dates for all products in each bin and prioritize picking accordingly. Additionally, we can initiate purge tasks for items not picked within the required timeframe.

How many bins and what size grid will I need to cover my SKU range?

The number of bins and grid size a customer needs depends on your product range and turnover. Bin quantity and type (plastic or metal) will also affect grid size. Calculations consider stock bins, buffering, cells and level of safety features required (dictated by bin type). For precise requirements, please get in touch.

Does the grid require fire baffles, barriers or breaks?

In traditional cubic ASRS systems using bins constructed of combustible material, fire breaks are recommended to help control horizontal flame spread. In many cases, permanent vertical barriers will be deemed necessary by local fire services. Our new solid-sided metal bins shield stock from direct flame impingement. In doing so, they effectively partition the grid into thousands of individual fireproof boxes. This also enables the removal of fire breaks required of some solutions, resulting in the reclamation of up to 20 percent of cubic storage space, a reduced (or better leveraged) physical footprint, and lower real estate costs.

Can you install into brownfield or operating sites?

The modular design of the Ocado Storage and Retrieval System (OSRS) grid allows for straightforward installation in nearly any type of facility, whether it's a new construction site (greenfield) or an existing one (brownfield), regardless of size, shape, or location. It can even be installed across multiple stories and in regions of high seismic activity, with bin lifts enabling connectivity between floors. For sites with live operations and immediate automation requirements within their existing infrastructure, our Chuck AMR solution can be rapidly deployed and has a shorter installation time than OSRS.

Can you install on a mezzanine?

Yes. Many of our chilled grids in grocery customer fulfillment centers (CFCs) operate in this fashion.

What's your data security policy? Are you SOC 2 compliant?

Yes, we are compliant with SOC 2, Type 2 data security standards, which assess a service organizations' controls and safeguards over time, focusing on security, availability, processing integrity, confidentiality, and privacy.

On-Grid Robotic Pick

On-Grid Robotic Pick Watch Now: System Benefits

Watch Now: System Benefits@4x.png?width=642&height=166&name=OIA_Logomark_color_(R)@4x.png)