Maximize Productivity.

Minimize Cost.

World-Proven Warehouse Automation for

Future-Proof Fulfillment Operations.

Honed By Over 20 Years of First-Hand Operational Experience.

Our products and solutions simplify and streamline many complex challenges facing modern supply chains today. They’re the result of over 20 years of R&D—informed by the experience of maximizing efficiency and minimizing costs in our own warehouses.

The Ocado Storage and Retrieval System (OSRS) is our flagship solution that revolutionizes automated order fulfillment. It’s engineered to elevate automated order fulfillment with unmatched efficiency, reliability, and scalability to meet the demands of very high throughput operations.

For businesses requiring scalability and deployment ease in medium to low throughput environments, our industry-leading Ocado Mobile Robot System (OMRS) combines advanced Fulfillment Execution Software with autonomous mobile robots (AMRs) to exceed customer expectations, grow profits, and reduce risk.

And our OCADEX robotic pick arms enable new levels of dexterity by manipulating stock items just as a human would. With the ability to learn the optimal way to pick up items, the OCADEX range is capable of handling individual eaches up to cases on pallets.

Simplifying & Streamlining Warehouse Operations.

Proven under pressure, our warehouse automation solutions effectively simplify and optimize today’s dynamic supply chain challenges.

With over 20 years of experience developing and operating our own automation technologies, leading brands trust OIA to automate and accelerate their warehouse operations.

Due to the inherent flexibility and scalability of our automation solutions, companies in industries from consumer retail to pharmaceuticals, industrial parts to third party logistics (3PL) can improve their supply chains and boost productivity.

Advanced digital modeling enables simulation, validation and optimization before we build anything in the real world—giving you full confidence in our solutions from day one. Once implemented, our robot orchestration software and ‘digital twin’ technology constantly optimizes your warehouse output.

Peerless Productivity

Our highly automated Warehouse Execution Software orchestrates pick station logic with bot movement to ensure bins arrive at the right time, maximizing operator productivity. The grid is also inherently self-sorting to prioritize order speed: faster-moving SKUs will naturally rise to the top of the grid.

System-Directed Picking

By leveraging our patented, system-directed algorithms, businesses can use data to optimize throughput without relying on employee judgment to calculate task allocation and path planning. This data can further be used to identify opportunities to fine-tune your operations in an increasingly competitive landscape.

Systems Overview

Discover the full suite of Ocado Intelligent Automation solutions–whether you need a solution capable of fulfilling 50 orders per day, or 150,000+.

A cubic automated storage and retrieval system (ASRS) with industry-leading storage density and throughput.

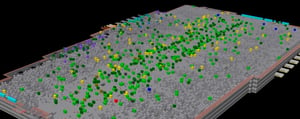

Robots navigate and fetch items from a fixed grid containing bins stacked up to 21 units high, orchestrated by our Warehouse Execution Software.

The easy-to-deploy autonomous mobile robot (AMR) system designed to boost efficiency and productivity in your warehouse operations.

Our collaborative robot cart Chuck and pallet-moving Porter combine autonomous hardware with intelligent cloud-based orchestration software to streamline warehouse workflows, from picking to putaway.

OCADEX Robotic Arms

OCADEX technology seamlessly integrates and augments our systems with the ability to pick, manipulate and sort using robotic arms.

Equipped with AI-powered reinforcement learning and computer vision, and supported by behavioral cloning, OCADEX robotic arms learn the optimal way to handle objects they’ve never encountered before, sharing this knowledge globally.

Virtual Warehouse Tour

World-proven automation and business intelligence combine to make up the Ocado Storage and Retrieval System. Get to know the components that make up OSRS.

Latest News & Media

Read the latest news and press on Ocado Intelligent Automation, plus Ocado Storage and Retrieval System (OSRS) and Chuck/AMR solutions.

@4x.png?width=642&height=166&name=OIA_Logomark_color_(R)@4x.png)