OMRS / Chuck

Chuck AMR

The Workhorse for Any Warehouse.

Chuck is an autonomous mobile robot (AMR) designed for rapid deployment and collaboration with your employees. It’s currently used to solve automation challenges in over 100 sites across Europe and North America.

Chuck is designed to optimize fulfillment workflows in warehouses of all sizes. Collaborating with workers and other Chucks via powerful cloud orchestration software and utilizing system directed picking, Chuck is one of the largest, most adaptable and most flexible fulfillment AMRs available today.

With best-in-class configurability, including a wide variety of accessories, Chuck suits any warehouse. A true ‘cobot’, Chuck is here to help your employees work and stay on task more effectively, leading them via system-directed prompts to minimize walking, carrying and pulling. Adaptive navigation technology allows Chuck to move rapidly yet safely through busy warehouse environments, avoiding obstacles while maintaining the most efficient routing.

Key Benefits

Reduce Total Cost of Ownership

OMRS requires 40–60% fewer AMRs than leading competitors. This translates to less congestion, lower maintenance and greatly simplified operations, resulting in long-term cost savings.

Steve Lewis,

VP of Solutions & Strategy, GXO

“We’re seeing an 80% reduction in the actual time it takes to train someone. We’re also seeing a lift in retention of labor. With the removal of long walks and a lot of the physical work, the job is easier.”

Over 1 Billion Units Picked

Optimal Routing and Task Accuracy

Clear next-task instructions with visual previews and floor view maps eliminate confusion, ensuring optimal routes and picks every time and significantly reducing costly fulfillment mistakes.

Hundreds of Millions of Orders Processed

Let Chuck Do The Heavy Lifting

By outsourcing manual labor to our AMR, your employees cut down on strenuous manual activity—walking, carrying, and pulling tasks. This fosters improved safety, comfort, and satisfaction among the workforce.

Rapid Deployment and Training

Chuck can be deployed into your existing infrastructure or greenfield sites–in weeks rather than months, while simple, fast training reduces downtime and operational impact, allowing new staff to achieve full productivity in minutes, not days.

Features

Chuck is a game-changer for modern warehouses, combining advanced hardware and smart software into one AMR. Designed for efficiency, scalability, and ease of use, Chuck empowers teams to streamline their operations and work smarter, not harder.

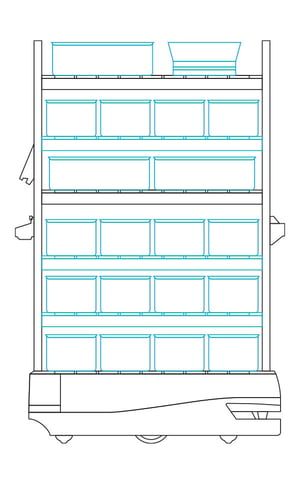

Chuck can be customized to suit a wide range of operational needs (see configurations, below). Our range of accessories includes up to six shelves, canopies, clothing hangers, ladders and even mobile label printers.

Each Chuck can carry dozens of orders at once, with a payload of up to 200 pounds or 90 kg. Need to handle wide or bulky items? Chuck+ provides an additional 6in / 15.25cm on each level giving you an additional 6.5 cubic feet /.184 cubic meters increase in volume capacity.

Advanced computer vision, AI, and ML guide Chuck safely through busy warehouses, avoiding obstacles and enhancing overall operational flow. Our patented safety system is CE compliant and has received UL and CSA certifications.

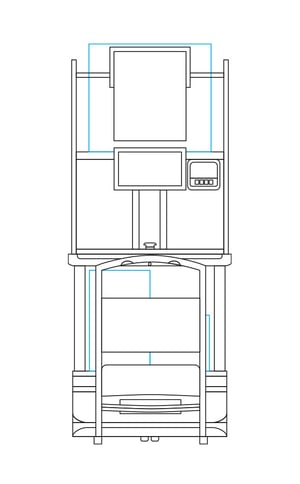

Chuck’s intuitive touchscreen display reduces onboarding to 15 minutes and gives associates all the SKU information they need for fast, accurate system-directed picking and putaway.

Long-lasting batteries with fully autonomous charging keep your Chuck fleet running 24/7, ensuring near-uninterrupted operation throughout even the busiest shifts. Depending on payload, Chuck can go up to 12 hours on a single charge.

Configurations

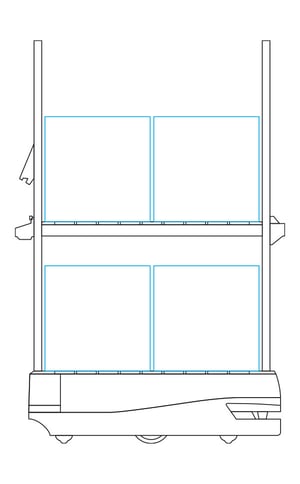

Pick direct to outbound carton for easy order pack-out

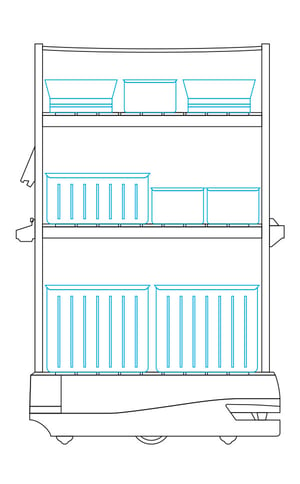

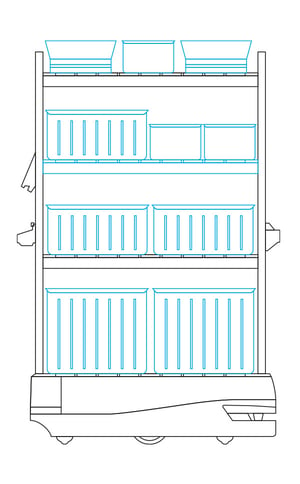

Pick to multiple tote and outbound carton sizes, plus storage canopy for trash and accessory handling

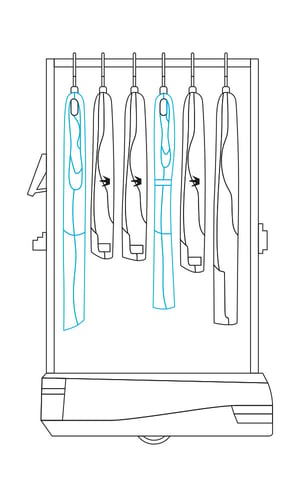

Garment on Hanger (GOH) picking for non polybagged apparel items

Support for mixed picking methods: discrete, batch, cluster, zone

Configurable up to 6 shelf levels with custom height increments of 0.5"

Support for mobile printing, ladders, workspace tray and other accessories

FAQ

Frequently asked questions about the Chuck AMR (Autonomous Mobile Robot).

Technical Specifications

DIMENSIONS:

- Overall Height: 63 in (160 cm)

- Base Width: 24 in (61 cm)

- Base Depth: 42 in (106.7 cm)

- Top Canopy Dimensions: 22.5 in × 36 in (58 cm × 91 cm)

- Chuck Shelf Dimensions: 23.75 in × 36 in (60 cm × 91 cm)

- Chuck+ Shelf Dimensions: 29.75 in × 36 in (75 cm × 91 cm)

WEIGHTS:

- Base Unit (no shelves):

- 127 lb (57.6 kg) without battery

- 154 lb (69.9 kg) with battery

- Battery Weight: 27 lb (12.2 kg)

- Chuck Per Shelf Weight: 15 lb (6.8 kg)

- Chuck+ Per Shelf Weight: 19.4 lb (8.8 kg)

- Chuck+ Base Level Width Extender Weight: 12 lb (5.4 kg)

- Total Capacity (Base Unit, no shelves): 215 lb (97.5 kg)

- Per Shelf Capacity: 100 lb (45.4 kg)

- Top Canopy Capacity: 30 lb (13.6 kg)

TECHNICAL:

- Battery: 25.6V, 42Ah

- Wi-Fi: IEEE 802.11a/b/g/n/ac Wireless LAN 2T2R

OPERATING CONDITIONS:

- Operating Temperature: 2° C (36° F) to 35° C (95° F)

- Storage Temperature (>30 days): -20° C (-4° F) to 25° C (77° F)

- Transit Temperature (<30 days): -45° C (-49° F) to 60° C (140° F)

- Charging Temperature: 6° C (43° F) to 35° C (95° F)

- Relative Humidity: Up to 65% (non-condensing)

- Elevation: -100 m to 2000 m

- Floor Surfaces: Concrete, ResinDek® with TriGard®

- Floor Flatness: FF 25

- Floor Expansion Joint Gaps: Up to 19 mm (0.75 in)

- Floor Elevation Changes: Up to 6.4 mm (0.25 in)

- Live Load (Uniform Distributed Load): 250 kg/m² (51 lb/ft²)

- Lighting for Camera: Minimum: 5 fc (54 lux); Recommended: 10 fc (108 lux)

- ATEX: Not suitable for potentially explosive environments

@4x.png?width=642&height=166&name=OIA_Logomark_color_(R)@4x.png)